1. Introduction to Machine Vision

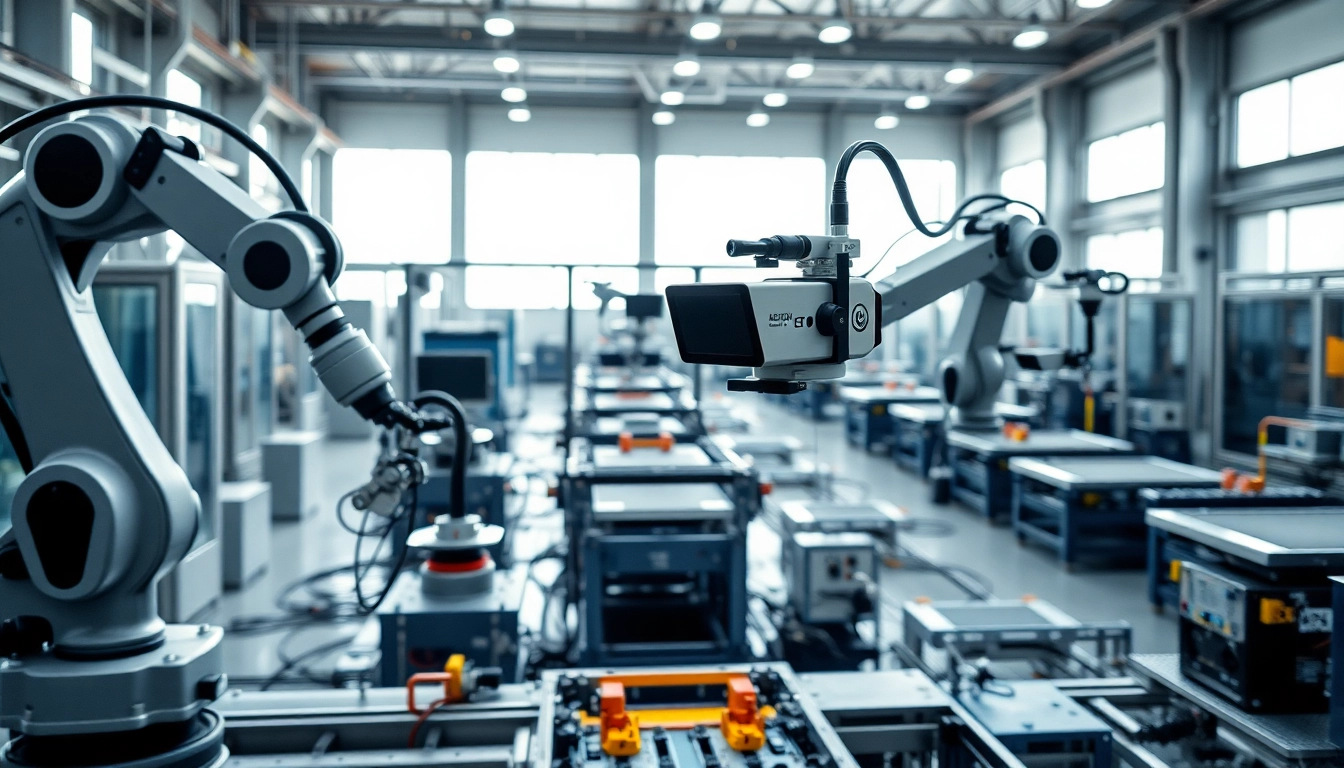

In today’s fast-paced industrial landscape, the integration of technology has become crucial for enhancing efficiency and reliability in various processes. One of the most profound advancements in automation technology is machine vision, a domain that empowers machines to interpret and understand visual information. By employing sophisticated imaging technologies and algorithms, machine vision systems facilitate automated inspections, guiding robotic assemblies, and significantly enhancing product quality. This article delves into the intricacies of machine vision, from its foundational components to its diverse applications, innovative technologies, and future trends.

1.1 What is Machine Vision?

Machine vision refers to the technology and methods used to provide automatic inspection and analysis by capturing images and interpreting visual information. This technology combines various components—including cameras, lighting, and software—for processing images. The essence of machine vision lies in its ability to replicate the human ability to see and understand qualitative details in its environment, but with a speed and accuracy that far exceeds human capabilities.

1.2 Importance of Machine Vision in Industry

The role of machine vision in industrial settings is multifaceted and indispensable. It enhances operational efficiency, reduces human error, ensures consistent product quality, and facilitates data-driven decision-making. Industries like manufacturing, automotive, and electronics rely heavily on machine vision systems for performing tasks such as quality control, assembly guidance, and defect detection. In rapidly changing markets, the ability to adapt quickly and maintain high standards can offer significant competitive advantages.

1.3 Basic Components of Machine Vision Systems

A machine vision system typically consists of four core components:

- Cameras: These devices capture visual information. Depending on the application, cameras can be 1D, 2D, or 3D, equipped with different types of sensors to capture varying details.

- Lighting: Proper lighting is crucial for obtaining clear and accurate images. The type of lighting can greatly influence the quality of the image and the effectiveness of the inspection process.

- Processing Hardware: This includes computers or specialized processors that analyze the images captured. Advanced processing capabilities allow the system to execute complex algorithms for real-time decision-making.

- Software: Machine vision software interprets the images and provides functionalities for automated inspection, defect detection, and various analyses. Many systems integrate artificial intelligence to enhance processing capabilities further.

2. Applications of Machine Vision

Machine vision finds its applications across numerous sectors, including manufacturing, healthcare, logistics, and automotive industries. Its versatility is largely attributed to its capability to adapt to various tasks through specialized configurations and software. Below are some prominent applications of machine vision:

2.1 Quality Control and Inspection

One of the chief applications of machine vision is quality control in manufacturing settings. Automated inspection systems are employed to perform defect detection, measurement, and verification tasks. By leveraging high-resolution cameras and intelligent algorithms, these systems can rapidly identify defects in products that are often imperceptible to the human eye. This capability not only reduces waste and rework but also guarantees that only products meeting stipulated quality standards reach the market.

2.2 Robotics and Automation

In robotics, machine vision plays a crucial role in enhancing the functionality and precision of robots. Systems equipped with vision capabilities enable robots to interact with their environment more intelligently, allowing for tasks such as sorting, navigation, and assembly. For instance, vision-guided robots can pick up items from conveyor belts or other locations, identify where to place them, and execute the action with high accuracy. This contributes to smoother workflows and improves overall operational efficiency.

2.3 Medical and Healthcare Applications

Machine vision technology is also making significant strides in the healthcare sector. From analyzing medical images (like X-rays and MRIs) for diagnostics to automating processes within laboratories, machine vision helps enhance patient safety and operational efficiency. For example, automated systems can monitor medical equipment supplies and ensure that necessary resources are available to medical staff without making errors that could endanger patient care.

3. Types of Machine Vision Systems

Choosing the right machine vision system requires understanding the various types available and their respective functionalities. The following outlines the predominant categories of machine vision systems:

3.1 1D, 2D, and 3D Vision Systems

Machine vision systems can be categorized based on the dimensionality of the data they process:

- 1D Vision Systems: These systems typically involve sensors that process linear data, often used in applications like barcode scanning.

- 2D Vision Systems: 2D systems analyze images captured in two dimensions. They are widely used for applications like product inspection and quality control, where flat images are sufficient for decision-making.

- 3D Vision Systems: These systems analyze three-dimensional shapes and surfaces, providing detailed information about the volume and spatial relationships of objects. They are beneficial in complex applications such as robotics, where depth perception is vital.

3.2 Spectral Imaging and Color Vision

Machine vision systems are now being equipped with spectral imaging capabilities, which enable them to capture and analyze images across different wavelengths of light. This ability enhances their applications in various fields such as food safety, agriculture, and quality control by allowing for the detection of materials based on their spectral signatures. Similarly, color vision systems can discern variations in color that are crucial for ensuring products meet specific standards.

3.3 Choosing the Right System

Selecting the appropriate machine vision system involves evaluating several factors including application requirements, budget constraints, and existing manufacturing processes. Considerations such as the level of detail required, the complexity of the environment, and specific industry standards will guide the decision-making process. Collaborating with machine vision specialists can assist organizations in selecting systems that align seamlessly with their operational goals.

4. Innovations in Machine Vision Technology

The field of machine vision is marked by rapid innovations, introducing advanced methods that enhance its functionality and effectiveness across various applications. This section highlights some of the most significant innovations in machine vision technology.

4.1 Integration with AI and Machine Learning

The integration of artificial intelligence (AI) and machine learning into machine vision systems has revolutionized their capabilities. By facilitating advanced image pattern recognition and predictive analytics, AI-powered systems enable enhanced defect detection, anomaly identification, and overall decision-making quality. Machine learning algorithms facilitate continuous improvement as they learn and adapt from previous analyses, thus refining their performance over time.

4.2 Future Trends in Machine Vision

The future of machine vision promises further integration with Internet of Things (IoT) technologies, leading to more seamless data communication and interconnected monitoring systems. These advancements will enable real-time inspections and provide actionable insights on quality metrics, process efficiency, and supply chain optimization. Additionally, the proliferation of edge computing solutions will support quicker processing of visual data at the source, minimizing latency and enhancing operational responsiveness.

4.3 Challenges and Limitations

Despite the remarkable capabilities of machine vision, several challenges still exist. Issues such as environmental factors (e.g., insufficient lighting, dust, or object reflection) can degrade image quality and hinder system performance. Additionally, the initial cost of implementation and the need for ongoing system updates and refinements can present barriers for some organizations. Ensuring comprehensive training for operators is also crucial for maximizing the effectiveness of machine vision applications.

5. Best Practices for Implementing Machine Vision Systems

Successfully implementing machine vision systems requires careful planning, strategic execution, and ongoing monitoring. Businesses can follow these best practices to optimize the deployment of machine vision technology:

5.1 Steps for Effective Implementation

The implementation of machine vision should follow a structured process:

- Define Clear Objectives: Outline specific goals and performance metrics for the machine vision system that align with the overall business strategy.

- Evaluate Existing Systems: Conduct an analysis of current processes to identify areas where improvements can be made through machine vision.

- Select Appropriate Technology: Choose the suitable type of cameras, lighting, and software that meet the specific requirements of the intended application.

- Engage Stakeholders: Involving staff from different departments during the planning stages can lead to comprehensive input and enhanced buy-in for the implementation.

- Develop a Training Program: Ensure that operators and staff receive adequate training on the new systems to facilitate smooth integrations and foster a culture of continual learning.

5.2 Measuring Performance Metrics

Once implemented, it is essential to continuously monitor the system’s performance against predefined metrics. Some common performance indicators include:

- Accuracy: Measure the reliability of defect detection and decision-making processes.

- Processing Speed: Evaluate how quickly images are processed and decisions are made, affecting overall throughput.

- System Downtime: Track the amount of time the system is offline and identify areas for improvement.

- Return on Investment (ROI): Analyze the financial benefits derived from implementing machine vision, including cost savings and increased revenue.

5.3 Real-World Case Studies

Numerous companies across various industries have successfully implemented machine vision systems, demonstrating substantial benefits:

- Automotive Industry: Leading automotive manufacturers have adopted machine vision for quality control, achieving defect detection rates exceeding 99% and significantly reducing assembly line rework.

- Pharmaceutical Sector: Pharmaceutical companies utilize machine vision to ensure drug packaging quality, enhancing safety and regulatory compliance while decreasing inspection times and errors.

- Food Industry: Food processing companies leverage machine vision to inspect product quality, ensuring that substandard items are automatically discarded, thus ensuring consumer safety.