Understanding Electromagnetic Shielding Materials

Electromagnetic shielding materials play a crucial role in protecting electronic devices and systems from electromagnetic interference (EMI). By obstructing unwanted electromagnetic signals, these materials prevent damage and ensure optimal performance. The demand for reliable electromagnetic shielding materials is growing in various industries, including telecommunications, aerospace, automotive, and healthcare. Understanding the nature, types, and applications of these materials is essential for engineers and designers to implement effective shielding solutions.

What Are Electromagnetic Shielding Materials?

Electromagnetic shielding materials are substances designed to block or attenuate electromagnetic fields. This technology is vital due to the increasing prevalence of electronic devices, which generate electromagnetic radiation as a byproduct of their operation. Shielding materials can be classified based on their composition, structure, and shielding effectiveness. These materials can be applied in a range of forms, from conductive coatings to complex enclosures used in sophisticated electronic equipment.

The Science Behind Electromagnetic Shielding

The fundamental principle behind electromagnetic shielding lies in the interaction between electromagnetic radiation and conductive materials. When electromagnetic waves encounter a conductive surface, the free electrons in the metal can absorb or reflect the energy of the incoming waves, thereby preventing them from penetrating into sensitive areas. The effectiveness of shielding depends on several factors, including the frequency of the electromagnetic waves, the thickness of the material, and the type of material used.

Common Applications of Shielding Materials

Electromagnetic shielding materials are utilized across a vast array of applications. Common uses include:

- Consumer Electronics: Laptops, smartphones, and other gadgets employ shielding to protect internal circuits from interference.

- Medical Devices: MRI machines and other diagnostics tools require effective shielding to operate without interference from external electromagnetic sources.

- Telecommunications: Shielding is critical in cell towers, routers, and other communications devices to ensure signal clarity and protect sensitive circuitry.

- Aerospace and Defense: Aircraft and military equipment utilize robust shielding to prevent EMI, which can affect navigation and communication systems.

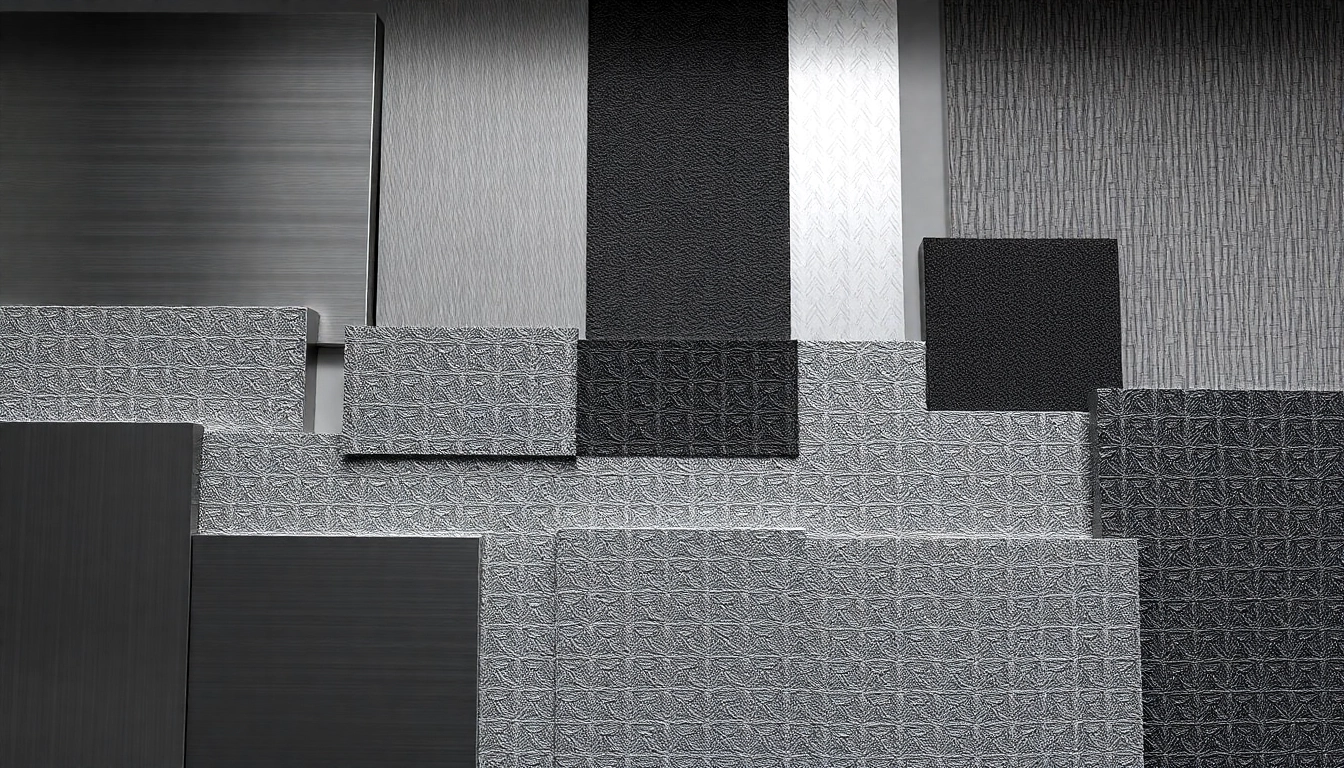

Types of Electromagnetic Shielding Materials

Metals: Advantages and Disadvantages

Metals are the most commonly used materials for electromagnetic shielding due to their high electrical conductivity. Here are some of the most popular metals used in EMI shielding:

- Copper: Highly efficient at blocking both magnetic and electrical interference. Lightweight and malleable but can corrode over time.

- Aluminum: Offers a good balance of weight and shielding effectiveness, with excellent resistance to corrosion.

- Steel: Provides high durability and effective shielding but is heavier compared to other metals.

- Nickel: Generally used as a coating over other metals for additional protection and shielding effectiveness.

Each metal has its pros and cons, and the choice depends on the specific application requirements, including cost, weight, and environmental factors.

Conductive Polymers: A Modern Approach

Recently, conductive polymers have emerged as a significant player in electromagnetic shielding. These materials combine the flexibility of plastics with the electrical conductivity of metals, offering several unique advantages:

- Flexibility: Unlike metals, conductive polymers can be easily molded into complex shapes.

- Weight: They are significantly lighter than traditional metal shields, making them ideal for applications requiring weight reduction.

- Cost-effective: Commonly cheaper to produce, they can offer a competitive alternative to metallic shielding.

However, they often exhibit lower shielding effectiveness than metals, especially at high frequencies. Research is ongoing to enhance the performance of conductive polymers and expand their applications.

Foams and Composites for Shielding

Foam and composite materials have gained traction in specific applications, especially where weight and space constraints are critical. Shielding foams typically incorporate conductive materials within a polymer matrix, providing lightweight, effective shielding. Composites can offer tailored properties by combining different materials to enhance performance. Some common applications include:

- Automotive: Lightweight shielding foams are used in vehicles to reduce EMI from electronic control units.

- Telecommunication: Foamed materials help create lightweight and efficient enclosures for communication devices.

Choosing the Right Electromagnetic Shielding Material

Factors to Consider in Material Selection

Choosing the correct electromagnetic shielding material involves evaluating several critical factors:

- Frequency Range: Different materials react to varying frequency ranges. Ensure the selected material provides effective shielding for the intended application.

- Environmental Resistance: Depending on exposure conditions (such as moisture, heat, or corrosive elements), select a material that maintains its shielding properties over time.

- Weight and Space Constraints: In applications such as aerospace and military, the weight of shielding is paramount; lightweight materials may be preferred.

Performance Metrics and Testing Methods

To determine the effectiveness of electromagnetic shielding materials, various testing methods are employed:

- Shielding Effectiveness (SE): Measured in decibels (dB), SE quantifies how much electromagnetic radiation is attenuated by the shielding material.

- Reflection Loss: This measures how much electromagnetic energy is reflected away from a material’s surface.

- Transmission Loss: Reflects the strength of the electromagnetic waves that pass through the shield material.

Shortlisting Based on Applications

After considering the factors and performance metrics, you can shortlist potential materials based on the specific application requirements. For instance, medical devices may prioritize high-frequency shielding effectiveness and biocompatibility, while automotive applications might prefer lightweight and rugged materials.

Best Practices for Implementing Shielding Solutions

Design Considerations for Shielding

Effective design is critical in implementing electromagnetic shielding solutions successfully. Here are essential considerations to keep in mind:

- Continuous Shielding: Ensure that the shielding material is continuous without gaps or openings to achieve maximum effectiveness.

- Grounding: Proper grounding techniques enhance shielding performance by providing a path for absorbed electromagnetic energy.

- Material Compatibility: When using multiple shielding materials, confirm their compatibility to prevent galvanic corrosion and ensure effective performance.

Installation Techniques for Optimal Effectiveness

The installation of electromagnetic shielding materials can significantly impact their effectiveness. Below are some common installation techniques:

- The Use of Gaskets: We recommend using conductive seals and gaskets at joints and interfaces to minimize electromagnetic leakage.

- Layering Techniques: Using multiple layers of different materials can lead to improved performance.

- Space Management: Allow for adequate space within enclosures to avoid compaction and ensure effective air circulation.

Maintenance and Troubleshooting Shielding Solutions

Regular maintenance ensures that electromagnetic shielding continues to perform its role. Here are some strategies for maintaining shielding solutions:

- Periodic Inspections: Regularly check for signs of wear, corrosion, or damage to shielding materials.

- Cleaning Protocols: Follow appropriate cleaning protocols to avoid compromising the shielding material’s integrity.

- Testing: Conduct routine tests to evaluate the continuing effectiveness of the shielding materials over time.

The Future of Electromagnetic Shielding Materials

Innovations in Shielding Technologies

As technology evolves, so do shielding materials and their applications. Emerging innovations include:

- Nanotechnology: Advances in nanomaterials can lead to improved performance in terms of both weight and effectiveness.

- Smart Materials: Materials that can change their properties in response to external stimuli hold potential for dynamic shielding solutions.

Sustainability in Shielding Material Development

Sustainability is becoming increasingly important in material development. Innovations focusing on eco-friendly materials and manufacturing processes are being prioritized, reducing the environmental impact of electromagnetic shielding solutions.

The Impact of Evolving Regulations on Material Choices

As governments worldwide implement stricter regulations regarding EMC (Electromagnetic Compatibility) and environmental standards, manufacturers must adapt their shielding strategies and material choices to comply with these evolving regulations. This shift may influence the selection of specific materials, encouraging the use of sustainable and proven effective options in the industry.