In the fast-paced world of manufacturing and logistics, efficient packaging solutions have become a cornerstone of operational effectiveness. When it comes to liquid products, selecting the right machinery and partnering with a reliable Liquid Packaging Machine Supplier is crucial for ensuring quality, speed, and cost-efficiency. This comprehensive guide explores liquid packaging machines, details various types and their applications, highlights essential supplier features, outlines the benefits of partnerships, shares compelling success stories, and provides actionable insights for getting started with your liquid packaging needs.

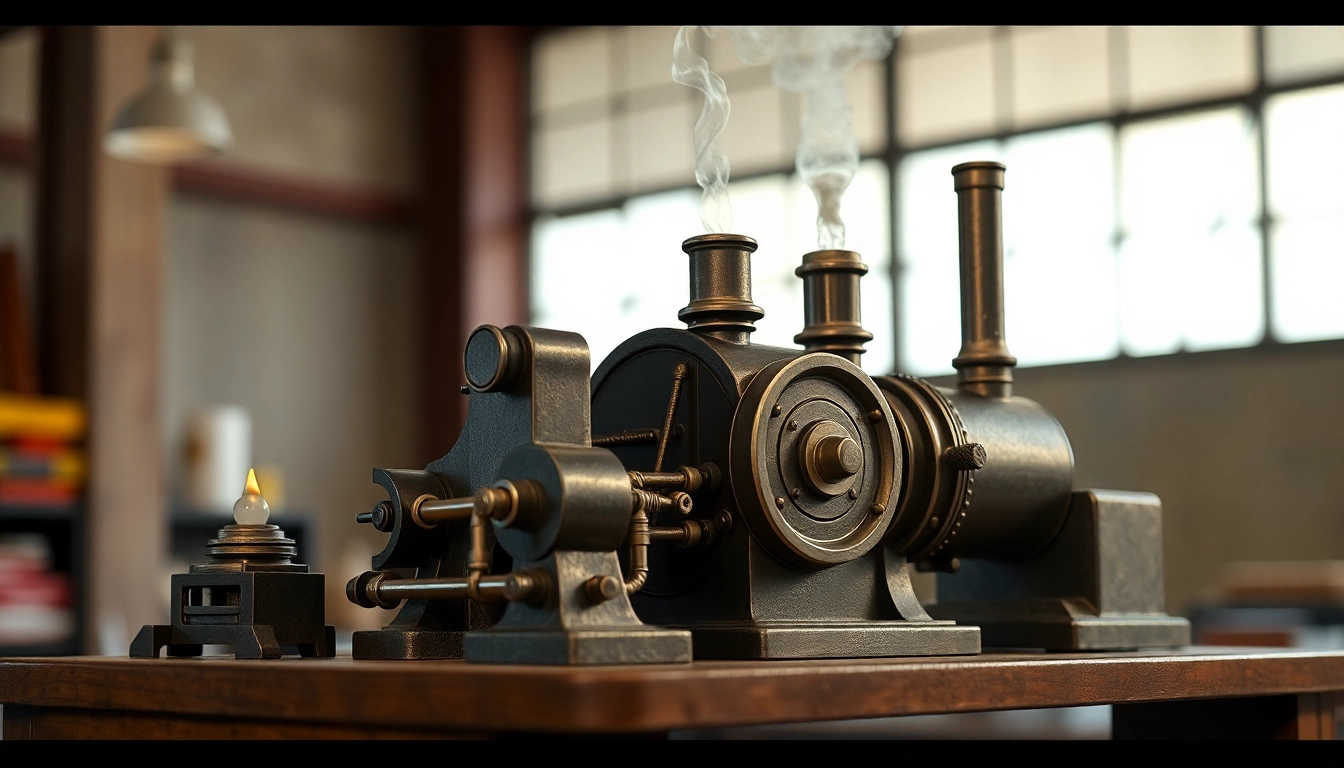

Understanding Liquid Packaging Machines

Types of Liquid Packaging Machines

Liquid packaging machines come in various forms, engineered to cater to an array of liquid products in distinct industries. Here are the primary types of liquid packaging machines:

- Liquid Fillers: These machines are designed to fill containers with liquid products. They can be categorized into several types:

- Piston Fillers: Ideal for thick liquids and pastes, using a piston to dispense precise volumes.

- Overflow Fillers: Suitable for thin liquids, exiting through the top of the container.

- Gravity Fillers: Operate using gravity; best for free-flowing products.

- Sealers: After filling, these machines seal the containers using various techniques—heat sealing for plastic, induction sealing for aluminum, etc.

- Labelers: Essential for branding and compliance, these machines apply labels to packaging, which can include variable data printing.

- Cartoners: They package filled containers into boxes or cartons for shipment, streamlining logistics.

Industry Applications

Liquid packaging machines cater to a broad spectrum of industries, including:

- Food and Beverage: Beverages, sauces, oils, and dairy products require specialized machinery to ensure safety and quality.

- Pharmaceutical: Medicines and health products must be packaged under stringent regulations to uphold safety.

- Chemicals: Harsh chemicals require robust machines capable of handling corrosive substances.

- Cosmetics: Creams, lotions, and other liquid products need precision and aesthetic packaging for market appeal.

Choosing the Right Machine

Selecting the right liquid packaging machine involves considering several key factors:

- Product Characteristics: Thickness, viscosity, and reactivity of the liquid influence machine choice.

- Production Volume: Higher volumes may require more automated systems for efficiency.

- Budget Constraints: Understand the total cost of ownership, including machine acquisition, maintenance, and operational costs.

- Filling Accuracy: Necessary for ensuring product consistency, especially in food and pharmaceutical industries.

Key Features to Look for in a Supplier

Quality Assurance and Certifications

When evaluating potential suppliers, quality assurance is paramount. Look for certifications such as ISO 9001, which indicates a quality management system is in place, and certifications specific to the industry, like FDA compliance for food packaging. Ensure that the equipment meets international safety standards, which can protect your business from liabilities.

Technical Support and Services

A reputable supplier offers extensive support post-purchase. This includes installation services, regular maintenance, and prompt troubleshooting assistance. Efficient technical support can significantly minimize downtime, which is vital for maintaining smooth operations.

Customization Options

Every business is unique, and often, off-the-shelf machines won’t meet specific needs. A supplier who can provide customization options tailored to your product requirements—be it adjustments in filling volume, speed modifications, or integration with existing systems—will add great value.

Benefits of Partnering with a Trusted Supplier

Cost Efficiency

Working with a reliable liquid packaging machine supplier can yield significant cost savings. Trusted suppliers provide durable equipment that requires less frequent repairs and maintenance, resulting in lower operational costs. Bulk purchasing agreements can also bring down unit costs.

Latest Technology Integration

Investing in solutions that incorporate the latest technology can enhance productivity and reduce waste. For instance, advanced filling machines can offer faster throughput and precise filling—the difference in technology translates into more efficient operations and reduced costs.

Scalability and Flexibility

A good supplier understands that businesses grow and evolve. They provide machines that can be scaled up or adjusted, allowing for easy upgrades or new functionality without the need for a complete overhaul, maintaining efficiency and saving on future investment costs.

Case Studies: Success Stories

Food and Beverage Sector

One prominent case involves a beverage manufacturing company that struggled with bottling inefficiencies. By partnering with a leading packaging supplier, they upgraded to a high-speed filling system designed for beverages. The result? A 30% increase in production rates and a significant decrease in spillages, leading to cost savings.

Pharmaceutical Applications

A pharmaceutical company faced challenges adhering to strict regulatory requirements for liquid medicines. Implementing fully automated filling machines provided them with accurate dosing, keeping them compliant with industry standards while increasing production efficiency by 50% compared to their previous manual processes.

Cosmetic Industry Examples

In the cosmetics sector, a skincare brand needed a solution to package its new line of serums. By collaborating with a flexible liquid packaging machine supplier, they achieved bespoke packaging that not only maintained product integrity but also resonated with their brand image. This strategic move allowed them to launch their product within unpredictable timelines successfully.

Getting Started with Your Liquid Packaging Needs

Assessment of Packaging Requirements

Begin by assessing your specific packaging needs, including product properties, desired output rates, and regulatory requirements. Understanding these factors will provide clarity on the types of machinery appropriate for your operations.

Consultation Process

Engage with suppliers who offer a comprehensive consultation process. They should analyze your current setup, discuss challenges, and propose tailored solutions. This personalized approach ensures you invest in machinery that aligns with your goals and operational requirements.

Installation and Training Procedures

Once you’ve selected a machine, the supplier should facilitate the installation process effortlessly. Comprehensive training for your staff is vital for ensuring safe operation and adherence to best practices. Look for suppliers who provide ongoing support and further training as needed.